- Value Chain Excellence

- Company Business Performance

- Supply Chain Performance

- Supply Chain Strategy

- Integrated business management (S&OP)

- Digital Transformation

- Operational Improvement

- Transparency

- Complexity

- Agility

- Responsiveness

- Customer Needs

- Delivery Reliability

- SC Segmentation

- Inventory optimization

- Throughput Times

- Order Management

- Planning Excellence

- Cost management

- Logistics Cost

- Working Capital Optimization

- Supplier Optimization

- Transport Optimization

- Network Optimization

- Post Merger Integration

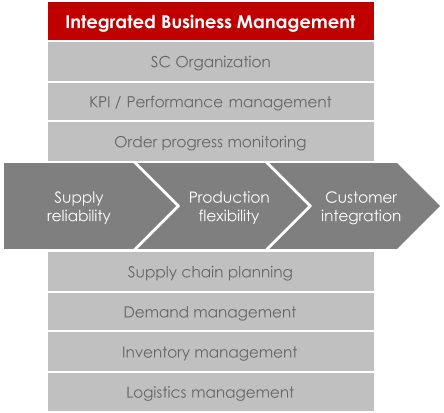

INTEGRATED BUSINESS MANAGEMENT

Integration of Demand and Supply possibilities in the Sales,

Inventory, Operations Planning leads to success in overall

business management

•

The methods developed in Sales and Operations Planning

(S&OP) are well known, and well proven in the general field of

supply chain management. Yet, many companies still struggle

to really see, understand, and benefit from the full impact of

this typically monthly alignment process to gear the supply

chain to superb performance, meeting the always changing

market needs.

•

The first challenge is to establish the process as such, to get all

relevant paricipants as delegates of their functions, to

participate in a regular, and prepared way. To take it serious,

see the value, and have them engaged and motivated.

•

Second challenge is to have the right set of information, so that

the participants have compatible data, and do not surprise

each other by presenting some information out of a “magic

source”. Many companies have mastered this challenge by all

participants working real-time in the same data environment.

•

Third challenge is to find the right mode for making decisions.

This involves clarity for decision processes within the meeting,

and also regulations and definitions for decisions which need a

different setting to come to the right decision. In this context, a

good scheme of escalation procedures is vital to keep the

process, and its results, on track.

•

Another challenge is to find the right frequency, the right

regional and organizational scope, and the suitable reach of

the time horizons. Although monthly cycles and 12 months of

reach are most common (some use 2, others 3 months cycles),

it needs to fit to the needs of the business. And linking local,

regional, and global operations also requires a specific solution

to bring the intended value for the business.

•

And, finally on the “top-item-list”, general management needs

to agree to the scenarios presented, the insights and findings,

and also support the results, and decisions made. Ideally, top

management sees this process as a means to reduce the many

firefighting meetings happening manifold, and also replaces

many of the “regular reporting meetings”. And on this basis

manages the whole value chain, and the company, on the

back of this highly vital process.

•

From an IT enabler perspective, there is nowadays a high

number of solutions available, each with specific strenghts, and

application advantages. It is also not only about the numbers,

but increasingly about the communication to come to the

numbers and insights. Therefore advanced tools also include

elements of social media to replace cumbersome E-Mail-

Communication with embedded (and conserved) on-line

communication possibiliites.