- Value Chain Excellence

- Company Business Performance

- Supply Chain Performance

- Supply Chain Strategy

- Integrated business management (S&OP)

- Digital Transformation

- Operational Improvement

- Transparency

- Complexity

- Agility

- Responsiveness

- Customer Needs

- Delivery Reliability

- SC Segmentation

- Inventory optimization

- Throughput Times

- Order Management

- Planning Excellence

- Cost management

- Logistics Cost

- Working Capital Optimization

- Supplier Optimization

- Transport Optimization

- Network Optimization

- Post Merger Integration

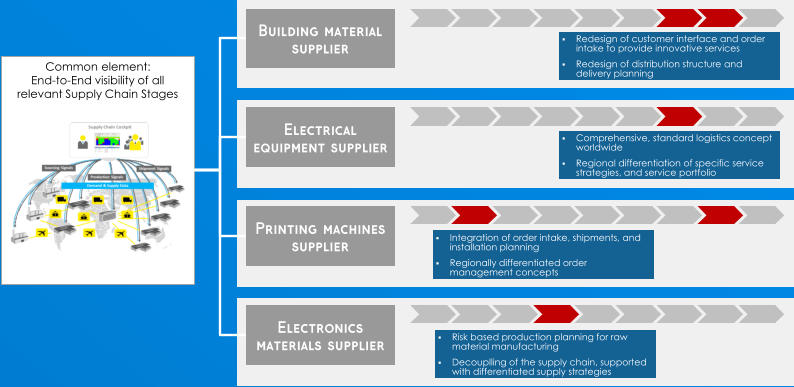

SUPPLY CHAIN PERFORMACE IMPROVEMENTS

Supply Chain Performance has

many faces

•

For every industry, and also for

every type of organization,

there is a specific area which is

at a certain point in time the

limiting factor for high supply

chain performance

•

There are typical areas in which

some key “leading practices”

should be applied to enhance

the performance. But in most

companies it requires a very

specific setup for these

practices to unfold their value

•

The specific methods

developed and applied by IN-

NOVA ensure that the most

important “sweet spots” are

adressed in the right way, and a

clear evolution towards the

required set of capabilities is

layed out.