- Value Chain Excellence

- Company Business Performance

- Supply Chain Performance

- Supply Chain Strategy

- Integrated business management (S&OP)

- Digital Transformation

- Operational Improvement

- Transparency

- Complexity

- Agility

- Responsiveness

- Customer Needs

- Delivery Reliability

- SC Segmentation

- Inventory optimization

- Throughput Times

- Order Management

- Planning Excellence

- Cost management

- Logistics Cost

- Working Capital Optimization

- Supplier Optimization

- Transport Optimization

- Network Optimization

- Post Merger Integration

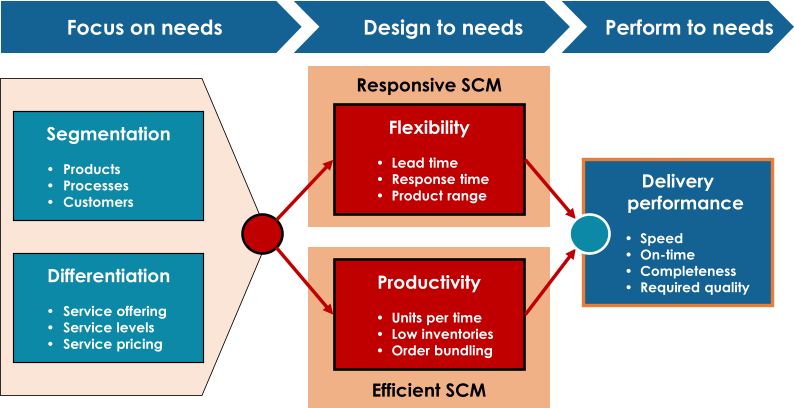

SUPPLY CHAIN STRATEGY

Successful strategic Supply

Chain Design

•

Segmentation according to

SC requirements

•

Differentiation of services

addressing these

requirements

•

Selection of either a

responsive, or an efficient

solution design

•

Orientation of solution

details on specific customer

segment delivery

performance designs

There are many different topics when talking about supply chain strategy…

In most projects with strategic context, the key question at the end is how to

deliver customers, and how to design the internal operations to do so.

This is more predominant than questions around warehouse locations, global

footprint or other high level topics. The latter one are also very important, and

need to be addressed in a strategic context, but in the end they all follow the

question to find the “best-fit” supply chain for all different customers, their needs,

their products, and the required delivery modes.

IN-NOVA pursues a very focused and effective approach to identify these best-fit

supply chains. In many clients we have found a more “one-size-fits-all” approach

when it comes to supply chain design. But even before the emergence of digital

business, and the challenges from the digital transformation, it is mostly necessary

to build a set of very different supply chains within the company. The variety of

requirements is too high, and to address these with a narrow set of supply chain

possibilities, leads to high cost, insufficient service levels, and a lot of other

negative side effects.

In our experience, the journey starts with a good segmentation. But not a

marketing driven segmentation, but a segmentation driven by specific

requirements of products, production processes, distribution requirements, and

customer need types.

Your own journey towards a high-impact, high-value supply chain strategy

Based on a clever segmentation, it is a challenging but also rewarding task to

come up with a number of very differentiated ways to purchase materials, produce

the product, distribute it, and link specific service elements, and even pricing

elements to it. Of course, also order taking, inventory management, and many

other elements offer opportunities for differentiatioin.

The following design of the various supply chains which are required to make and

distribute the products is based on two distinctly different base models:

•

An efficient supply chain is typically very “low cost” driven. This is the classic

domain of cost management, but it also needs significant considerations of

delivery capability. This type of supply chain is suitable in a low-change

environment, often with high volumes, or high number of similar transactions.

Downside is that it offers little room for adjustments, or individuality.

•

A responsive supply chain is required when predictability of a future state is very

limited, or the variety of the requested product or service is very high. As a

result, buffers and other flexibility elements are required to provide the

necessary short term reaction capability. But, of course, cost-control is always

an important part of supply chain management. Therefore it is often necessary

to break down the overall (end-to-end) supply chain in individual brackets, and

to identify the inherent supply chain logic for each step. Based on these insights,

a multi-stage supply chain design can be developed, providing the right level

of flexibility, but still bundling for scale-efficiencies where possible.

But there are many more “tricks to the trade” which we will be happy to explore

together with you for your individual supply chain scenario!