- Value Chain Excellence

- Company Business Performance

- Supply Chain Performance

- Supply Chain Strategy

- Integrated business management (S&OP)

- Digital Transformation

- Operational Improvement

- Transparency

- Complexity

- Agility

- Responsiveness

- Customer Needs

- Delivery Reliability

- SC Segmentation

- Inventory optimization

- Throughput Times

- Order Management

- Planning Excellence

- Cost management

- Logistics Cost

- Working Capital Optimization

- Supplier Optimization

- Transport Optimization

- Network Optimization

- Post Merger Integration

LOGISTICS COST OPTIMIZATION

In a supply chain, there are always two main focus areas for

cost optimization

•

In our assessments, we look initially at all relevant areas to

optimize logistics cost - but only on a very high level, to

understand the mechanics of the business, and the current

performance levels of our client.

•

Based on these high level insights, we develop a deeper

understanding what drives the logistics cost, and from there

to look into the two main levers for optimizing logistics cost.

•

The two main levers are factor cost (spend per unit), and

avoiding unnecessary cost. We prefer the second lever, as

the first one is already exploited based on decades of

purchase price optimization. But we also often run into the

need to have a fresh look at the first one…

•

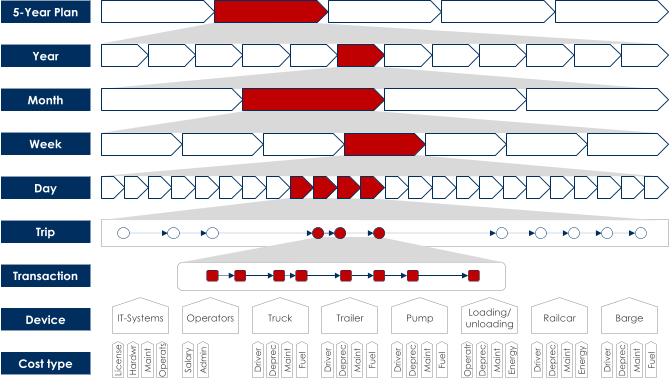

By using a modified “Activity Based Costing” approach, we

can clearly identify the areas of factor cost influence (the

device and cost type levels), and the transaction levels

which drive how much of the cost is created.

•

The model also allows to see how often the transactions

happen, in a similar way, or in different ways, in different time

buckets. On that basis it is possible to identify other sets of

measures to influence the cost position - and also the

performance position.

•

When having created such a high-level transparency with a

very detailed backing of information, a wide range of

possible improvements can be identified, quantified, and

evaluated in their performance impact.

Logistics, Transport, and Distribution

networks offer plenty of opportunities for

improvement

•

There are many topics in logistics which

offer opportunities for improvement. This

is driven by the many participants,

interactions, and processes along the

logistics chain.

•

Typical strategic topics cover distribution

network design, number and role of

warehouses, selection of transportation

service providers and their given roles,

outsourcing of warehouse services, and

collaboration with sales and distribution

channels. There are many themes and

approaches, and every company will

need a different perspective and set of

improvements at a different point in

time. Therefore individual analysis, and

approach design, is a key driver for

performance enhancements

•

On the operational and transactional

level, the nature of improvements is

different - besides optimizing how a task

is conducted, the initial question should

be how to avoid the necessity to do this

task. Or to do it in a completely different

way. A core driver of logistics cost is the

number of transactions - the higher the

transaction volume, the higher the cost.

Although often economies of scale

apply, the starting question is often to

understand what drives the number of

transactions. And if a lot of emergency

shipments are due to late availability of

the parts, it is not a question of logistcs

cost per se…

•

Processes meet technology - a very

large part of improvements, and

changes to current setups and

infrastructures, resides in the new abilities

derived from clever IT systems, used in a

clever way. The magic of “digital

transformation” is very visible in this

space, even including the potentials of

3D-Printing, and other technologies

which reshape how products get to

customers. Or even when digital

products replace physical products

(music, photos, videos etc).