- Value Chain Excellence

- Company Business Performance

- Supply Chain Performance

- Supply Chain Strategy

- Integrated business management (S&OP)

- Digital Transformation

- Operational Improvement

- Transparency

- Complexity

- Agility

- Responsiveness

- Customer Needs

- Delivery Reliability

- SC Segmentation

- Inventory optimization

- Throughput Times

- Order Management

- Planning Excellence

- Cost management

- Logistics Cost

- Working Capital Optimization

- Supplier Optimization

- Transport Optimization

- Network Optimization

- Post Merger Integration

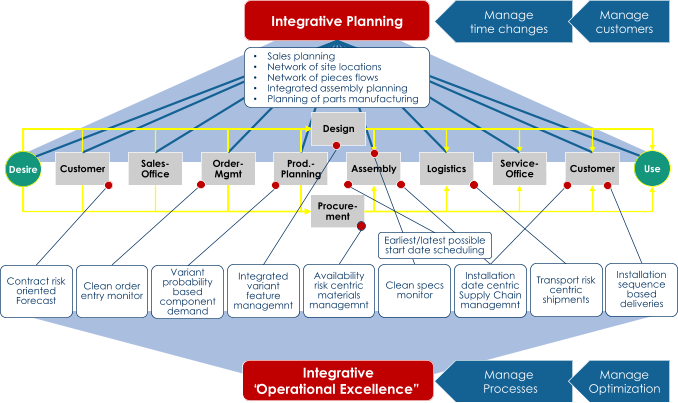

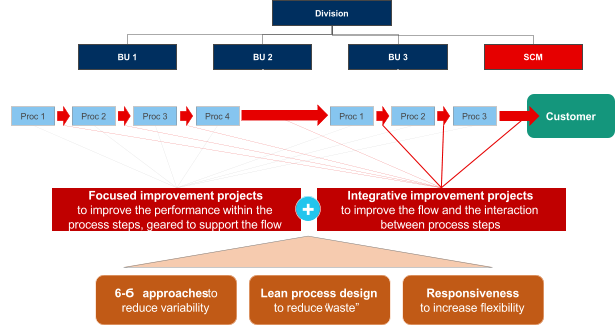

OPERATIONAL IMPROVEMENTS

In our supply chain excellence driven world,

operational improments need to serve the

overall flow

•

There are plenty of opportunities, every

day, to improve operational

performance. In every area of the supply

chain, and in the individual processes

•

But supply chains are highly networked;

internally, and also externally. In order to

achieve sustainable operational

improvements, there are two main

starting points for operational

improvements:

o

Integrative Planning: How to establish

planning and coordination

mechanisms which enable that the

plans of each area fit to each other,

and how to create seamless

information flows

o

Integrative “Operational Excellence”:

How to establish a very high level of

functional excellence in each area of

the supply chain, and the entire value

chain, to have highest performance

internally, but also to deliver the right

kind of information or products to the

other areas in the chain, in the quality

and timing they require.

•

In many companies, there is already a

legacy from decades of all kinds of

department based operational

improvements. But mostly these are within

the “walls”. The next level of improvement

quality is to work on functional excellence

improvements which drive the horizontal

excellence.

•

The exhibit provides some improvement

examples from a machinery client -

based on the individual orders, and often

project type of order and delivery

managemen of this industry, it results into

a specific set of required functional

excellence improvements which serve

the overall flow, and order progress. For

other companies, a different set of

measures will apply. And for other

industries as well

•

For more details on integrative planning,

see the planning excellence section.

In our service offerings, we identify how to shape your

operations towards higher performance levels:

•

Identification of strengths and weaknesses in key

processes of the supply chain related operations. In

order to focus your time and energy, we look at two

key processes which provide us with more than 80% of

the insights required for overall supply chain

performance enhancements, and value chain

optimization

•

Root cause and impact analysis on the weaknesses,

prioritization of the main obstacles and drivers of non-

performance, in order to identify which type of

improvement is required

•

Focus are measures which improve functional

excellence which serve the horizontal excellence. But

often we also find underrated vertical excellence as a

problem area, which will be included in the overall set

of suggested improvements

•

In this context, we often find the necessity for defining

and designing individual supply chain types (e.g. spare

parts vs new products; high volume production vs

specialty / customized production) which each then

might have a slightly different set of required (new)

enablers, and operational improvements

•

And, as always in our focus, define measures and

enablers for enhancing agility and resilience of

operations along the end-to-end supply chain

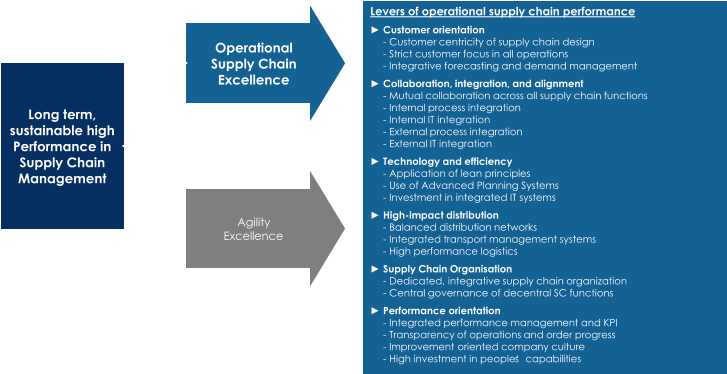

Leverage on insights regarding performance improvements

•

We reference in our work on the drivers of operational supply

chain excellence, identified during our research.

•

As important as considering these types of improvements, is to

implement measures increasing the agility level in the company

to cope with the challenges of today’s volatile business world.